Company Information

"RONENFORM" BG(a member of RGL) is dedicated to manufacturing series of Wires/Springs Forming Machines, Tubes Bending Forming Machines, and various auxiliary equipment and spare parts. The company is headquartered in Beijing, and its manufacturing workshop is located in Baoding and Cangzhou. It provides high quality equipment for domestic and foreign pipe and auto parts customers, with rich experiences of serving the industrial field for more than 20 years, "RONENFORM" becomes a reliable professional wire/tube forming equipment supplier and life time partner. "RONENFORM" does not only provide machines, but also the know-how on specific products thanks to backup by a technician team consists of many top professors-being called "Craftsman", we are confident to guarantee all our customers that our manufacturing level /serving level ranks at the top all over China. We follow up the principle of "ZERO FAULT"on each steps of business with you.

RONENFORM will always be here for you!

Metal Wire Forming Bending Machine Description

Fully-Auto Buckle Forming Galvanized Wire Mechinal 3D CNC Wire Bending Machine

American Market Quality Auto 3D CNC Wire Bender /Automatic 3D CNC Wire Forming Machine Metal Bending Machine/Steel Bar Bending Machine

American Market Quality Auto 3D CNC Wire Bender /Automatic 3D CNC Wire Forming Machine Metal Bending Machine/Steel Bar Bending Machine

Steel Wire Bending Machine Product Advantages:

Forming Wire Bending Machine Technical Parameter:

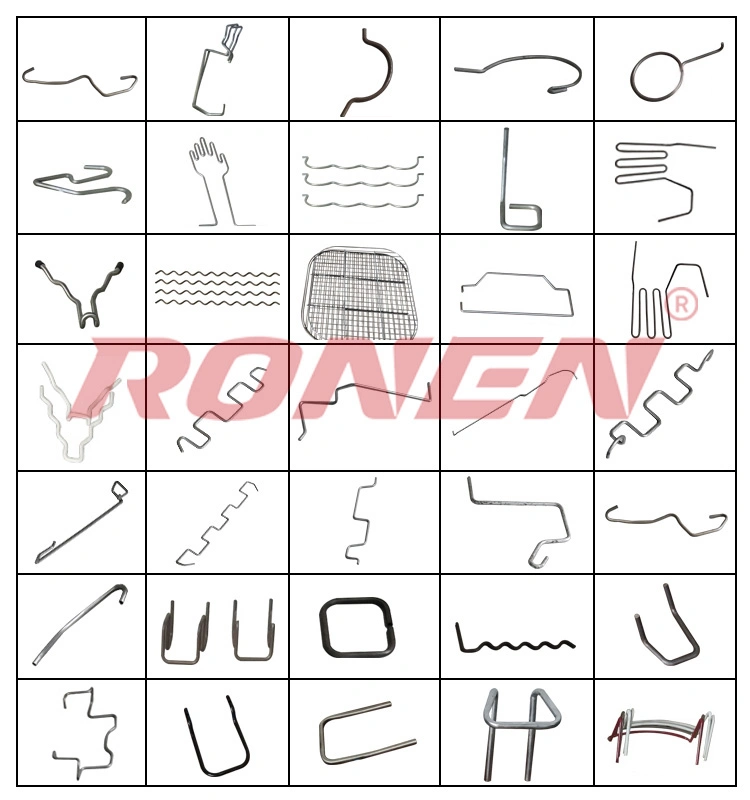

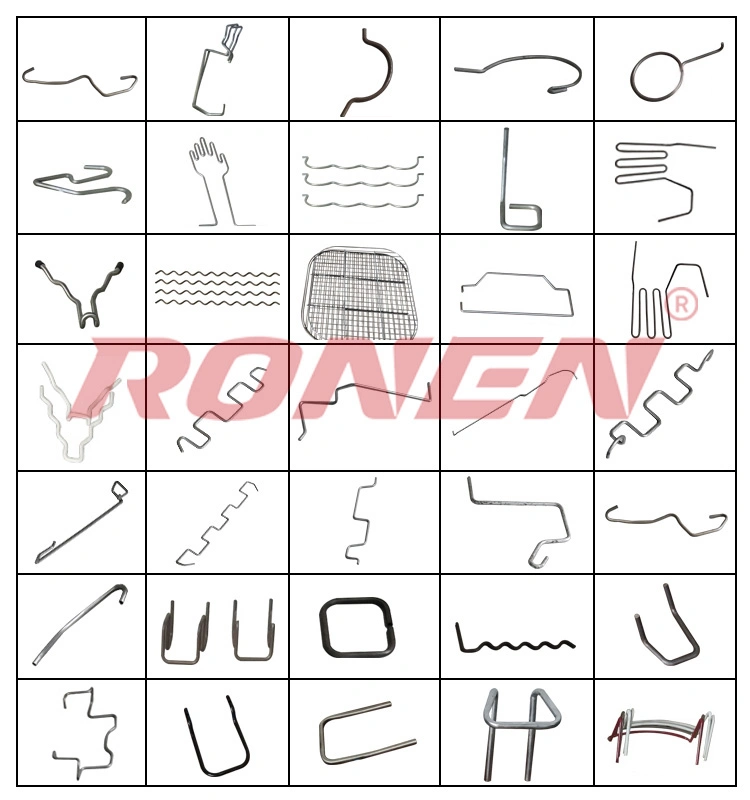

Ronen Group Related Products

Ronen Group Related Products

Ronen Group Exhibition Information

Certifications

Certifications

RONENFORM will always be here for you!

Metal Wire Forming Bending Machine Description

Fully-Auto Buckle Forming Galvanized Wire Mechinal 3D CNC Wire Bending Machine

American Market Quality Auto 3D CNC Wire Bender /Automatic 3D CNC Wire Forming Machine Metal Bending Machine/Steel Bar Bending Machine

American Market Quality Auto 3D CNC Wire Bender /Automatic 3D CNC Wire Forming Machine Metal Bending Machine/Steel Bar Bending Machine

Steel Wire Bending Machine Product Advantages:

1. In principle, the head turning molding machine has the advantages of no turning, light head structure and no turning, which ensures the fast and stable production

operation.

2. Computer power on, power off fast, simple and convenient operation. The computer interface can adjust the speed and change the program at the same time of

production.

3. High speed motor imported from Japan and reducer imported from Germany are used in the configuration. The production speed is more than 25% higher than that of

domestic counterparts.

4. Wire feeding and rotating arm are separated and matched. When the head is turned, the wire can not be turned, and the small outer diameter arc and multi circle

products can be formed.

5. The production can realize that the angle does not change at the slowest angle, and the production stability is better.

6. Bearing, gear and other important parts are imported from Taiwan, with 8760 hours guarantee, and the equipment is durable and reliable.

7. High precision, can do 2.0-14 mm wire diameter range of wire forming products, error reduced to 0.1 mm

8. The matching use of the steel wire butt joint machine makes the line changing operation of the machine more convenient.

operation.

2. Computer power on, power off fast, simple and convenient operation. The computer interface can adjust the speed and change the program at the same time of

production.

3. High speed motor imported from Japan and reducer imported from Germany are used in the configuration. The production speed is more than 25% higher than that of

domestic counterparts.

4. Wire feeding and rotating arm are separated and matched. When the head is turned, the wire can not be turned, and the small outer diameter arc and multi circle

products can be formed.

5. The production can realize that the angle does not change at the slowest angle, and the production stability is better.

6. Bearing, gear and other important parts are imported from Taiwan, with 8760 hours guarantee, and the equipment is durable and reliable.

7. High precision, can do 2.0-14 mm wire diameter range of wire forming products, error reduced to 0.1 mm

8. The matching use of the steel wire butt joint machine makes the line changing operation of the machine more convenient.

Forming Wire Bending Machine Technical Parameter:

| Project / Model | RN-06-6A | |

| Machining line diameter | 3.0mm - 6.0mm soft steel wire (20# steel) | |

| Maximum wire feeding speed | 50m/min | |

| The minimum time required to twist the head 90 degrees | 0.1s | |

| The minimum time required to reverse the transformation of the core | 0.2s | |

| The minimum time required to turn the line at 90 degrees | 0.2s | |

| Maximum lifting speed of torsion mechanism | 250mm/sec | |

| Maximum feed stroke | Unlimited | |

| Feeding mode | Roller feed line | |

| Maximum bending radius | 20mm | |

| Maximum bending angle | 180° | |

| Every set bending number | Unlimited | |

| Set number of files | Unlimited | |

| Working speed | Bending speed | 180°/0.5sec |

| Rotation speed | 360°/2sec | |

| Feed speed | 700mm/1sec | |

| Accuracy | Bending angle | ±0.05° |

| Angle of rotation | ±0.05° | |

| Material input mode | 1.numerical formula; 2. teaching method | |

| Controller | Industrial computer | |

| CNC data input | Touch screen input + hand wheel input | |

| Bending (C) servo motor power | 1.0 KW | |

| Rotating (B) servo motor power | 1.0 KW | |

| Power supply (Y) servomotor power | 2.0KW | |

| Electrical capacity | 15KVA | |

| Machine weight | 2000KG | |

| Machine size L*W*H(mm) | 2300*1600*1650MM | |

Ronen Group Related Products

Ronen Group Related Products

Ronen Group Exhibition Information

Certifications

Certifications

FAQ

1.Q:Are you manufacturer?

A:Yes, We are manufacturer.

2.Q: What are the payment terms?

A: Pattern of pattern :we can accept L/C ,T/T , Western Union , Money Gram

3. Q: What is the whole business flow cooperation with us ?

A:1.Firstly,send your inquiry to us,make us have learned your requirement

2.We will be drawing a proforma invoice according to your requirement ,and start production after you finished to pay

30% deposit.

3.All of the goods, packing details, and B/L copy will be send to buyer after finished production. We will arrange

shipment and provide original B/L after the buyer finished to pay the balance.

4. Q: What if you encounter technical problems?

A:Please contact us as soon as possible and let us know what kind of technical problems you encounter and the

details. We will give you a solution within 24 hours.

5. Q: What advantages we have?

A: Rich experience: We have been in this line for 20 years . we can provide solution according to the problem of the buyer meet in the production process.